Description

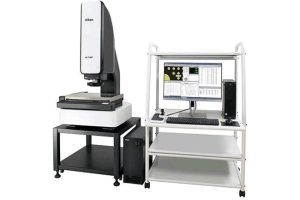

The iNEXIV VMA-2520 is a multi-sensor measuring system that is lightweight and compact enough to be used on a benchtop in a factory. With fast, fully automatic and high accuracy features make the VMA-2520 ideally suited for a wide variety of industrial measuring, inspection and quality control applications.

The iNEXIV is designed to measure 3D workpieces, it is touch probe ready, integrates with the latest imaging processing software and incorporates the new Nikon 10x optical zoom system and Laser Auto Focus option.

The iNEXIV VMA-2520 is primarily a non-contact, high-quality, optical inspection system that is optimized for speed and ease of use as well as for repeatable and accurate measurement of components.

The VMA-2520 can be equipped with laser Z-axis Auto Focus to join the standard video Auto Focus, with a choice available of a colour or black & white camera. Similarly, there are also alternative operating software packages to ensure the system is suited for each application environment, with expansion options including an interface for Renishaw® TP20 or TP200 touch probes. Specialist applications for small volume, high-value product development applications allowing rapid manufacturing adjustments based on fast and targeted measurement results.

Easy and accurate measurements optimized for 3D parts – Primarily a non-contact high-quality optical system with expansion options

- Optional laser z-axis Auto Focus to join standard video Auto Focus

- Optional Touch Probe capability, from the start or at a later date, interface provided as standard

- Colour or Black & White camera options available

- Choice of operating software for each application environment

Nikon has drawn on its state-of-the-art digital technologies to produce a highly affordable automated measurement system. The iNEXIV VMA-2520’s design is optimized for speed, ease of use as well as repeatable and accurate measurement of your parts and components.

Compact and lightweight – The iNEXIV VMA-2520 is a powerful and effective benchtop system designed to be used with minimum demand on the factory floor space. The main body has a footprint of only 565 W x 690 D x 740mm H (computer and controller separate) and weighs only 72kg (158.7 lb), yet it still has a 250 x 200 x 200mm (x,y,z) measuring capability.

Powerful VMA AutoMeasure software – Auto measure is Nikon’s powerful measuring software platform. The software provides user-friendly functions to easily conduct tasks ranging from initial setup, teaching programs and recorded instructions to easily have repeated measurements on to evaluations.

High-speed, high-accuracy Laser Auto Focus (optional) – In addition to the standard Vision Auto Focus, an optional high-speed Laser Auto Focus with a long 63mm working distance is also available. Which provides an even faster focusing and Z-axis measurements regardless of the surface or shape of your workpiece.

Touch probing measurement (optional) – The iNEXIV VMA-2520 accepts the Renishaw TP20 or TP200 Touch Probe systems, making surface and side coordinate measurement of complicated 3D parts possible, in areas where vision sensing hardware could not be used.

Users can then take full advantage of the multi-sensor capability when installing the optional CMM-Manager onto their iNEXIV system. The main features of this software is the collision-free CAD-based path definition, virtual path simulation and accurate feature measurement for both tactile and vision probing.

Long working distance – The developed optical system features a super long 73.5mm working distance for all magnifications. This impressive working distance allows sufficient and safe clearance for Z-axis measurements even at high magnification.