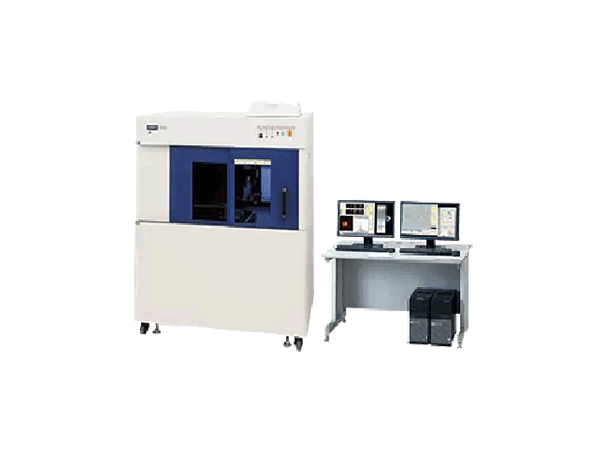

Description

EA8000A enables rapid detection and elemental identification of metal particles approximately 20 µm in diameter found in the electrode plates of fuel cells and lithium-ion rechargeable batteries. Metal particle contamination in electrode materials, separators of fuel cells, and lithium-ion rechargeable batteries causes heat and fire and decreases battery capacity and lifetime. When the measurement parameters are set, the EA8000A automatically captures X-ray images, detects, and identifies metal particles, enhancing the efficiency of failure analysis and testing.

20 um Particles Detected in Samples 250 x 200 mm in Just a Few Minutes – Conventional X-ray CT systems require about 10 hours to detect metal particles 20 µm in diameter in battery electrode plates 250 × 200 mm (about B4-size).

Automatic Particle Detection by Image Processing – EA8000A conducts high-speed image processing and detects particle position automatically over the entire 250 mm × 200 mm area using X-Ray image capture.

Automatic Elemental Identification of the Detected Particle – Fluorescent X-ray mapping at the particle location and automatic elemental identification can be performed.

Identification of Metal Particles in Battery Electrode plates – Conventional instruments are only able to identify metal particles 20 um in diameter when the particles are on the surface of the electrode plates. Signals from embedded metal particles are very small due to the absorption by the surrounding sample material. The EA8000A uses unique, focused X-ray optics to identify the elements in metal particles deeper within electrode plates and organic films.

All-in-one Instrument for Higher Efficiency – Detection speed and metal contaminants identification can be done in a much shorter time than conventional instruments. An X-ray imaging unit, fluorescent X-ray analyzer, and optical microscope are integrated into one system and linked to provide results automatically. The operator can simply place a sample and make measurements, resulting in efficient work and high throughput.

Key Features

- Best suited for inspections for compliance to RoHS, ELV and China RoHS , and safety inspection of toys and kitchenware.

- capable of non-destructive and quick analysis are now widely used to inspect the content of substances restricted by environmental directives represented by RoHS, ELV and China RoHS.

- No Liquid Nitrogen (LN2) Required

- Short Measurement Time

Specifications

- Particle Size – Down to 20 µm

- Detection Time – Approximately 3 to 10 minutes(imaging 250 × 200 mm)

- Elemental Analysis Time – Approximately 1 to 4 minutes per detection

- Elements – Atomic nos. 12 (Mg) to 92 (U)

- Sample State – Solid / Powder

- X-ray Angle – Bottom-up Irradiation

- Beam Size – 30 µm

- Fluorescent X-ray Detector – Vortex® (SDD) *No liquid nitrogen required

- Automatic Particle Analysis – X-Ray Imaging, metal particle detection, and elemental identification can be performed automatically.

- Particle Size Measurement – Detected particle size (projected area) can be measured automatically using X-Ray Image.