Description

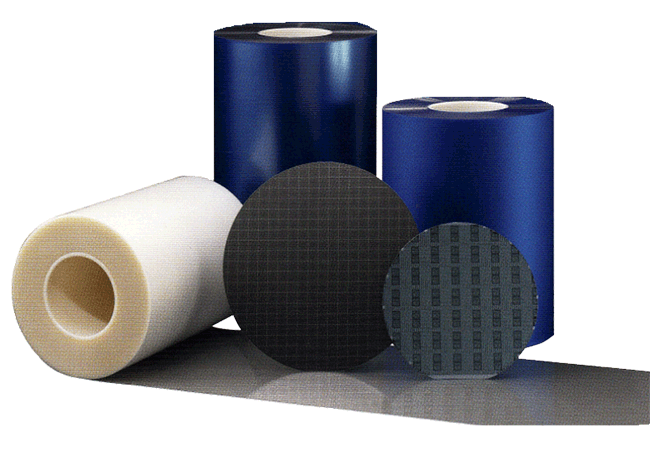

Back Grinding

Back grinding tape is used to protect the circuit surfacer from damage by foreign matter, chipping, cracking and contamination during the back grinding process. With developments of jumbo-sized and thinned wafer and high-bumped wafer, the function required to the BG tape are (1) low contamination levels, (2) highly close contact to wafer-, and (3) easiness of peeling. Elegrip BG tape meets these requirements. In addition, it is water-insoluble, making it effectively use around water and making washing unnecessary.

- Excellent adhesion to an uneven wafer surface, such as on the circuit side

- Effective control of particles

- Excellent grinding accuracy (TTV) and good water-seepage control during back grinding

- Easy peeling

- Effective control on adhesive deterioration with time

Dicing Tape

A dicing tape is used for fixing a workpiece during the dicing process in the manufacturing of semiconductors, electronic and optical components. With greater diversity and higher quality in chips, dicing tapes also require advanced technology. Elegrip dicing tape is used widely in a variety of applications including silicon and GaAs semiconductors (compound semiconductors), encapsulated package substrates, ceramics, glass, and crystals.

- Excellent control to back-side chipping and chip fly-off

- Excellent over-time stability (T Series)

- Excellent adhesiveness (shape-following properties)

- High performance to EMCs (Epoxy Mold Compounds) and other types of difficult-to-adhere workpieces

- Excellent expandability and smooth peeling