Work with the best integrated solution provider

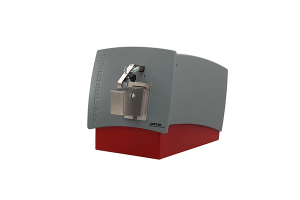

Arc Spark OES

To determine the chemical composition of metallic samples, Arc Spark OES is the preferred method. Metal manufacturers, foundries, diecasters, and primary producers use this process extensively. The most effective way to control the processing of alloys is through the use of arc spark optical emission spectroscopy systems. These systems are fast and accurate, which makes them ideal for controlling processing times.

In addition to in-coming material inspections, metal processing, quality control and other applications where the chemical composition of metallic materials is required, arc spark spectrometers can be used for many other aspects of the production cycle as well.

Showing all 5 results