Description

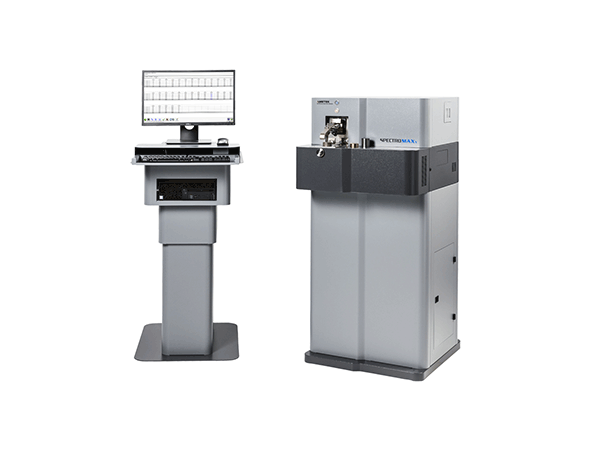

The SPECTROMAXx stationary metal analyzer is used primarily for materials testing in foundries and for incoming and outgoing inspection in the metal industry worldwide. It determines all elements used in the metal industry, including trace analysis of carbon, phosphorus, sulfur and nitrogen. The third generation of the SPECTROMAXx features improved operation with toolbar buttons, a user management system, and separation of operation from the instrument.

The measurement is no longer controlled via the menu, but rather via symbols and buttons in the toolbar. After starting an operation, only the functions that are logical at that time are active in the control software – all other commands are hidden. With the new application profiles, customer-specific information can be set before the start, which relieves the laboratory technician of administrative tasks.

The SPECTROMAXx independently monitors all operating parameters. It dynamically determines the required measurement time based on the given sample properties and even indicates when the spark stand must be cleaned, depending on the type of sample being examined.

The SPECTROMAXx arc/spark OES metal instrument severally monitors all operative parameters. It dynamically determines the measuring time needed supported the given sample properties and even shows once the spark stand must be clean counting on the sort of samples being examined. The elective AMECARE machine-to-machine (M2M) support permits proactive alerts, insured by direct reference to a distant SPECTRO service expert’s computer.

- Metal manufacturing

- Metal processing

- Analysis of precious metals

- Detection and Analysis of Inclusions

- Uncompromising; developed for high-analytical performance and low operating costs with minimal maintenance requirements

- Precise excitation with a complete digital plasma generator

- A robust special optic with a high-performance readout system

- Records the complete spectrum in the available wavelength range

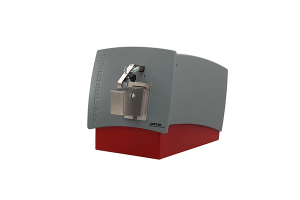

- Small part adapter with ready to analyze calibrations

- zero consumption during long work breaks

- Diagnosis system with innovative visualization functions