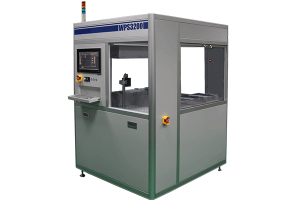

Description

WPS3800 is designed to handle 8” & 12” Wafer size for packing & from various of shipping carriers. The system comes with two load ports for 8” Semi Standard Open Cassette and 12” FOUP Cassette or 12” FOSB Cassette, two load ports for 8” Canister and 12” CanisterConfigurable to 1x Canister and 1x Wafer Jar with optional Cartesian robot module) and one port for interleaf paper (Auto-Conversion for 8” and 12” wafers). WPS3800 comes with a built-in vision sensor for the wafer, interleave paper or ring spacer detection and a built-in height sensor on the canister & wafer Jar loading port for the robot’s accuracy during the pick and place process.

Specifications

- Designed for 8” & 12” wafer

- Comes with 2 x FOUP/FOSB for 12” and Open Cassette for 8” with integrated

- Wafer Protrusion Detection Sensor and Thru-Beam Wafer Mapping

- 2 x Universal Shipping Carrier Station for various of Canister and Wafer Jar with auto-detection for 8” & 12” wafer size

- 1 x Interleaf Paper Port (Auto-conversion between 8” & 12” Paper)

- Built-in Hirata Wafer Pre-Aligner (8 & 12” wafers)

- Hirata 4-axis ATM robot with flip axis (Radius-Theta-Height-Flip Axes)

- 2-axis Cartesian Robot with Bernoulli Technique to handle Interleave Paper & Wafer

- Built-in Vision System for wafer, interleave paper or spacer detection

- Built-in Height Sensor for accurate robotic handling

- TCP-IP & RS232 data interfaces/ SECS/GEM data communication (Optional)