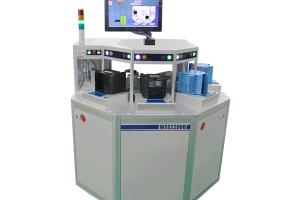

Description

The WHS2150W Wafer Weight Sorting System allows determining the weight of each wafer before it is sorted into a few of the clamshells or half-height open cassette. It is designed for 6″ of the wafer sizes. The wafer is transferred from open cassette to clamshell for Spin-Rinse-Dry (SRD) process. The weight of each wafer in a clamshell for the Pre-Rough process is determined. The wafer sort to the clamshell/half-height open cassette according to their weight loss range. All the wafers will be transferred back to the open cassette once all of the wafers achieve the weight required after going through the repeating SRD process.

Specifications

- Designed for 150mm Wafer

- Mettler Toledo High Precision Weighing Module, WXT Series with Custom Designed Enclosure.

- Hirata 4-Axis Dual Arm ATM Robot

- IOSS WID120 OCR into Hirata Pre-Aligner Module for 6” Wafer.

- 3 x Workcells with 4 Load Ports. LP1 for Peek Cassette, LP2, LP3 & LP4 with Universal Design to accept or Half-Height Open Cassette with Conversion.)

- HMI with Customized Software for Weight Sorting.

- TCP/IP Network Interface or SECS/GEM Data communication (Optional)