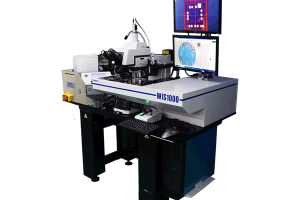

Description

WIS1000 is designed to handle 6” wafer and 8” wafer sizes. The standard design comes with one standard load port which can accommodate the 6” SEMI Standard Open Cassette and 8” SEMI Standard Open Cassette. The system is capable, wafer mapping and classification management. WIS1000 integrated with Nikon Wafer Auto-Loader and programmable XY indexing table for macro and micro inspection. It can perform macro inspection not only for the front wafer as well as the back wafer and micro inspection. Inker module can be integrated with the system for the defect marking during the inspection.

Specifications

- Designed for 150mm & 200mm Wafer

- Micro & Macro Inspection (Including Back Macro)

- Bright-Field, Dark-Field and NIC Modes

- Integrated with Nikon Autoloader & Microscope

- Motorized Objective Lens With 4 (5x, 10x, 20x, 50x)

- Integrated with Wafer Ionizer and Programmable XY Indexing

- Wafer Alignment & Wafer Mapping Capability

- User-defined Reject Code & Summary Lot Report after Inspection

- Integrated with Inker For Defects Marking (Optional)

- Software UI with Recipe Control Module, Wafer Map, Cassette Map and Microscope Components ‘Control