Description

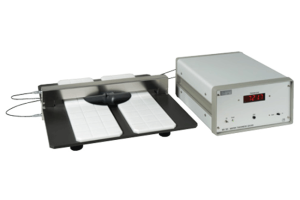

The E+H geometry gauges are based on two heavy plates mounted parallel to each other. Embedded in the plate is a set of capacitive distance sensors. The wafer will be moved manually or automatically between the plates and measured without any movement.

The gauge is based on two flat steel plates, mounted parallel to each other. Embedded in the upper probe head are 37 capacitive sensors. A manually operated kind of drawer moves the wafer into the air gap between the two plates.

The drawer is then lowered, the wafer comes to rest on the lower plate whose vacuum chuck is activated prior to the measurement. With every sensor in the upper probe plate, one measurement is performed. The measuring range covers the entire distance between the two plates at the given sensor position.

The dielectric of the inserted wafer at a given point affects the measured result and is proportional to its thickness there.

Applications

- Incoming inspection of Wafers

- R&D

- Qualification of processes

- In-process control for

- Thickness (e.g. backend)

- TTV

- Warp, FPD

- Stress